Can you meet production targets without production-oriented testing capabilities for the latest ultra-compact and high-cap MLCCs?

Exceptional performance is defined by industry leaders as high throughput and high reliability. ESI’s solutions for MLCC testing deliver just that. For decades ESI has been a leader in offering automated test, high-speed handling and visual inspection equipment for the manufacture of MLCCs and other passive components, including arrays, inductors and varistors.

Reliability, accuracy and high throughput for cost-effective MLCC testing.

Can you meet production targets without production-oriented testing capabilities for the latest ultra-compact and high-cap MLCCs? For industries facing material transformation challenges in production, we apply unique process and engineering expertise to deliver a set of laser-based solutions that extend our customers’ processing capabilities beyond the limitations of mechanical.

MLCC Testing Systems

Multi-layer ceramic capacitors (MLCCs) are used in volume in nearly all types of electronic circuitry. ESI's Allegro systems enable MLCC manufacturers to test these components with the accuracy, reliability and high throughput speeds needed to enable cost-effective high-volume manufacturing.

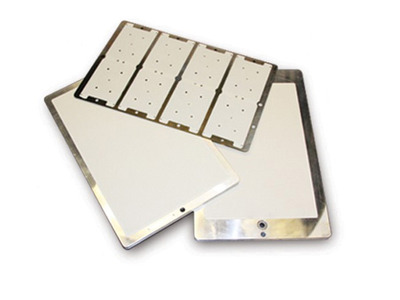

MLCC Tooling and Consumables

Quality replacement machine tooling maximizes performance for high-volume chip processing applications. ESI offers a broad selection of sizes and types of replacement tooling for our test and termination equipment to help you maximize throughput and minimize manufacturing downtime. As a leader in MLCC, ESI can address your needs for replacement carrier plates and belts for production MLCC processing.

- Silicone rubber carrier plates provide high-density loading of parts for high-volume chip processing operations.

- Quality replacement belts maximize high-density loading of parts for high-volume chip processing applications.

Ultra-High Velocity

Ultra-High Velocity