High-speed testing and sorting of ultra-compact, high-cap and general multilayer ceramic capacitors

- Verify quality and ensure accurate MLCC specifications

- Tests the smallest part sizes ranging from 0201-0603 (0603-1608 metric)

- Productivity rates of up to 1.2 million chips per hour See All Features

Features

High-Volume Testing of Multi-Layer Ceramic Capacitors (MLCCs)

Allegro is designed to help MLCC manufacturers meet the challenges associated with high-volume testing of even the smallest-size MLCCs. With its high-throughput testing capabilities, Allegro enables manufacturers to verify quality and ensure accurate specifications for the MLCCs used in the myriad electronic components and devices produced today.

MLCC Testing: High-Volume MLCC Testing with Allegro

Learn how Allegro tests high volumes of multi-layer ceramic components (MLCCs). Using ESI-pioneered technology, Allegro processes over one million MLCCs per hour.

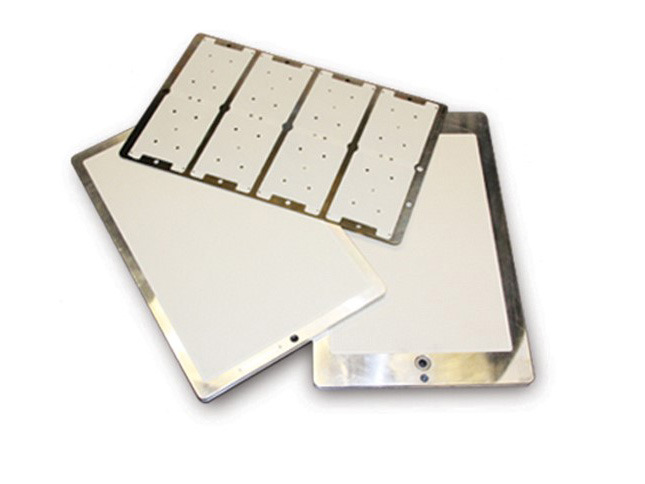

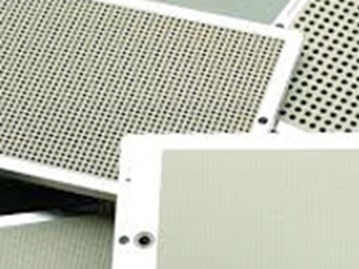

Process the Smallest Chip Sizes

Allegro has the flexibility to process even the smallest-size chip sizes down to 0201 (0603 metric) while testing performance in a range from <1 pF to 10 µF. It incorporates the automated eight-track testing capability pioneered by ESI, which means Allegro can process chips at speeds up to 20,000 per minute, while its advanced low-impact rotary handling technology, also pioneered by ESI, minimizes the potential for damage to the chips as the result of testing. This combination allows for consistently high throughput and higher testing yield.

Resources

Literature

ESI Laser Drill Systems(5.8 MB, PDF)