Application Notes

Filter by:

Application Note

Flex PCB Processing

As a leading provider of flex laser via drilling solutions, ESI applies decades of innovation and laser processing expertise to the challenges faced by customers focused on optimizing …

Application Note

Rigid PCB Processing

High-volume manufacturing of HDI PCBs requires blind (BHV) and through-hole (LTH) via processing; these vias are typically created with laser drills, which offer fast, reliable, and …

Application Note

Medical Device Metrology

Millions of stents, heart valves, and components are tested in the medical industry each year with ESI's portfolio of market-leading metrology systems. Our systems go beyond dimensional …

Application Note

Laser Based Micro Fabrication Systems for Electronics Packaging

Lasers are widely used in electronics packaging New end market demand requires rethinking of laser choices and system architectures. The system needs to provide high accuracy, high …

Application Note

Non-Copper Clad Dielectric Material Via Drilling

Dielectric materials where no copper cladding is required during lamination are typically used in semi-additive plating, modified semi-additive (mSAP), MLCC, or other such applicat …

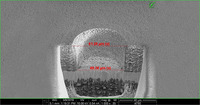

Application Note

Laser Direct Drilling (LDD)

Laser Direct Drilling is a process used for via formation (BVH & LTH) in a variety of dielectric materials, typically requiring some pre process preparation (thinned Cu, oxide treatment, …

Application Note

Comformal Mask Processing

In the Comformal Mask Drilling process, the top Cu is removed by chemical etching or UV Laser. The aperture is then used as a mask for CO2 drilling into the dielectric material.

Application Note

Discover the SPOT ON™ Advantage

SPOT ON™ increases performance by delivering a dynamic beam focus capability to high-production Flex PCB manufacturing. This capability enables beam location and control through automated …

Application Note

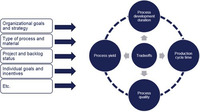

Process Development Tips and Tricks for Effective Flexible Circuit Laser Processes

Optimizing PCB laser processing for production requires a holistic view of the laser processes and their place in the production line. Taking the time to understand how those factors …

Application Note

How to Get Your New Flex System Installed and Processing Those First Runs

With your systems in place and your operators and process engineers fully trained, your team is now equipped to start developing and running production processes. However, it is common …

Application Note

Getting Your Facilities Ready for the Introduction of Laser Processing

With so many processes to keep track of in a flex manufacturing line, it can be easy to get lost in the details and begin to rely on your suppliers to address any issues that might …

Application Note

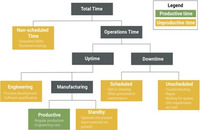

How to Calculate and Optimize Total System Cost of Ownership and Cost per Panel

When reviewing typical UV laser processing systems, upfront costs and maintenance costs make up the largest percentage of cost of ownership, with the majority of maintenance costs related …

Application Note

Manufacturing Flow and Considerations in Adopting Laser Processing Capabilities

There are several steps in the flexible circuit manufacturing process where laser processing can add value. This series will primarily focus on the laser micromachining processes related …

Application Note

MLCC Testing

For decades ESI has been a leader in offering automated test, high-speed handling and visual inspection equipment for the manufacture of MLCCs and other passive components, including …

Ultra-High Velocity

Ultra-High Velocity