Laser Direct Drilling (LDD)

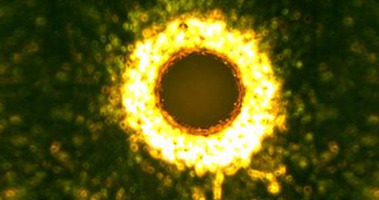

Laser Direct Drilling is a process used for via formation (BVH & LTH) in a variety of dielectric materials, typically requiring some pre process preparation (thinned Cu, oxide treatment, etc.). The first LDD pulse (or burst) is critical in this via drilling process, as it typically defines the via opening size and roundness.

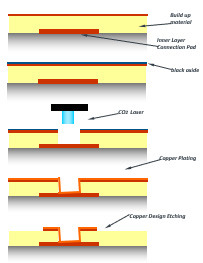

Laser Direct Drilling Process

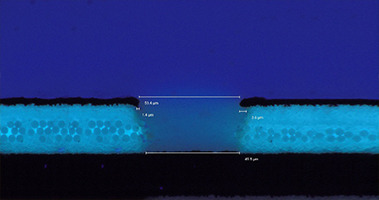

Figure 1. Laser direct drilling (LDD) process diagram.

Outer Cu Layer is Removed by Laser

- 12 um Cu: oxide required

- <3 um Cu: no oxide required

Process Limitations

- Cu thickness and aspect ratio may limit maximum diameter

- Infrared absorption of untreated Cu is very low and requires additional surface treatment to the outer layer of Cu such as an oxide ("black" or "brown")

- Oxide performance can vary (see next slide)

Advantages

- High throughput

- Low processing cost for HV

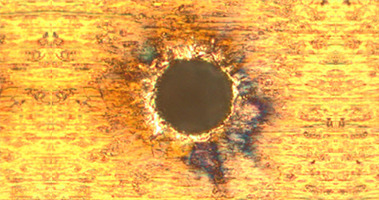

12 um Cu with Black Oxide Example

- System: Geode S

- Stackup: 12/42/30

- Sample size: 21

- OH - μm (µ/σ): 5.92/1.46

- Taper - % (µ/σ): 86.83/5.87

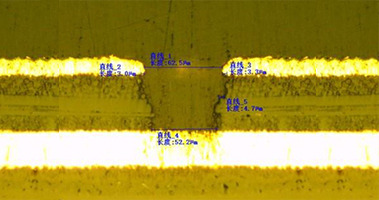

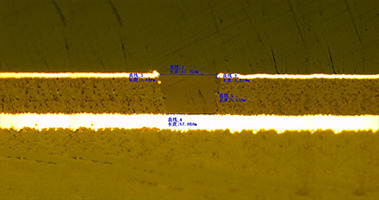

7 um Cu with Brown Oxide Example

- System: Geode L

- Stackup: 7/53/7

- Sample size: 25

- OH - μm (µ/σ): 4.0/1.0

- Taper - % (µ/σ): 81.2/4.3

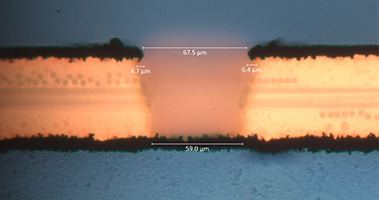

3 um Cu with Brown Oxide Example

- System: Geode S

- Stackup: 3/40/18

- Sample size: 26

- OH - μm (µ/σ): 4.7/1.33

- Taper - % (µ/σ): 86.11/3.75

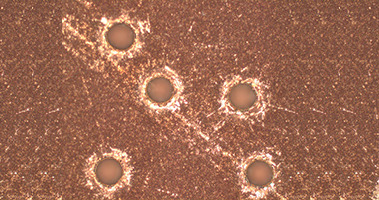

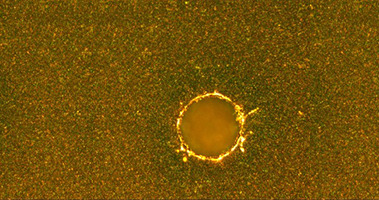

2 um Cu without Oxide Example

- System: Geode S

- Stackup: 2/35/NA

- Sample size: 20

- OH - μm (µ/σ): 4.1/1.1

- Taper - % (µ/σ): 94.8/7.0

Ultra-High Velocity

Ultra-High Velocity