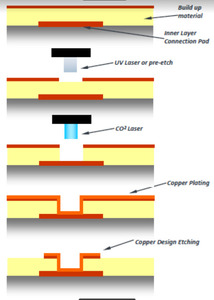

Comformal Mask Processing

In the Conformal Mask process, the top Cu is removed by chemical etching or UV Laser. The aperture is then used as a mask for CO2 drilling into the dielectric material.

Comformal Mask Drilling Process

Figure 1. Conformal mask drilling process diagram.

- Standard on >12 um Cu thinckness

Process Limitations

- The etching process doesn’t allow the alignment of the vias to the signal layer

- There is no correction of individual shrinkage orstretch possible

- Additional processes/systems required to remove Cu

Advantages

- No oxide treatment necessary

- Thicker outer layer Cu possible

- Typically low overhang

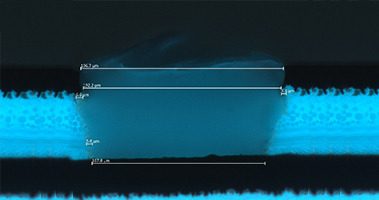

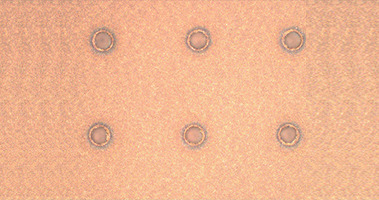

200 um via Example

- System: Geode L

- Stackup: 20/65/35

- Sample size: 106

- OH - μm (µ/σ): 7.6/2.4

- Taper - % (µ/σ): 94.1/5.1

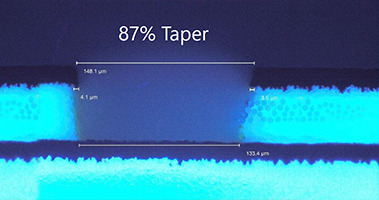

150 um via Example

- System: Geode L

- Stackup: 18/52/13

- Sample size: 20

- OH - μm (µ/σ): 3.6/1.8

- Taper - % (µ/σ): 86.7/4.3

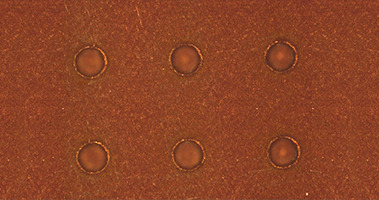

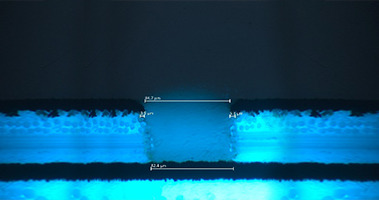

85 um via Example

- System: Geode L

- Stackup: 11/50/16

- Sample size: 60

- OH - μm (µ/σ): 4.09/2.38

- Taper - % (µ/σ): 92.8/0.05

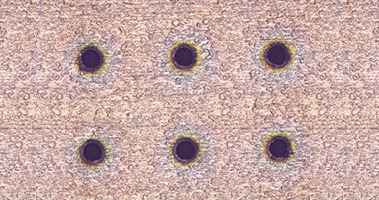

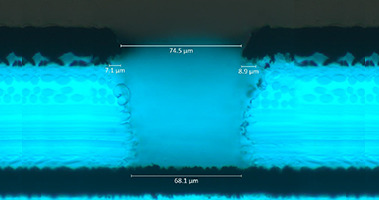

76 um via Example

- System: Geode S

- Stackup: 18/65/18

- Sample size: 20

- OH - μm (µ/σ): 7.99/2.09

- Taper - % (µ/σ): 80.68/3.46

Ultra-High Velocity

Ultra-High Velocity