Throughput Without Compromise

How Geode™ Maximizes Productivity

In high-volume PCB manufacturing, throughput is king. Traditional laser drilling systems often force a trade-off between speed and quality. Geode’s AcceleDrill technology breaks this paradigm by combining multi-ring and rectangle pulse strategies into a single-pass, high-efficiency process.

Author: Ryan Wagner

Released: July 17, 2025

Multi-Ring AcceleDrill

By embedding multiple concentric rings within a single pulse (e.g., 3x 5.6 µs pulses), In one customer example, Geode achieves an effective rep rate of 12.3 kHz at a nominal 4.1 kHz. This enables single-pass drilling of both vias and trenches.

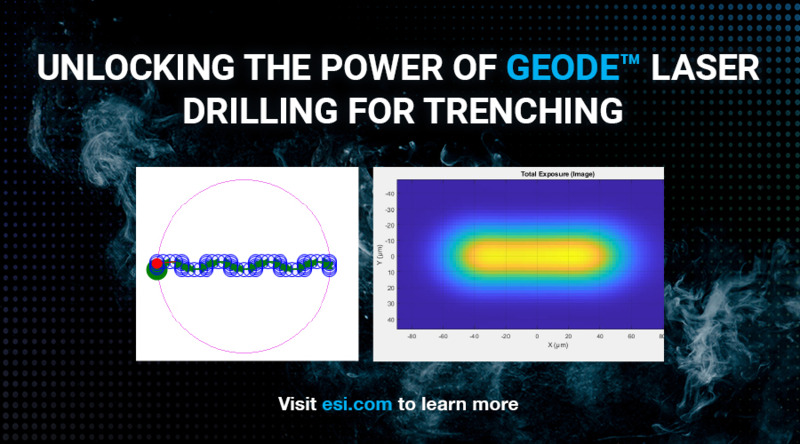

Rectangle AcceleDrill

For straight-line features, rectangular pulses deliver the highest throughput, especially on mSAP layers with thinner copper. However, this method is less suitable for curved or angled features due to overhang issues.

Throughput Gains

- Drill time using multi-ring and rectangle AcceleDrill files enables up to 44% faster processing over conventional trenching for certain processes

- Supports dynamic duty cycles and layer-specific optimization

Takeaway

Geode’s throughput advantage is not just theoretical, it’s proven in production. With flexible pulse strategies and smart toolpath conversion, it delivers unmatched speed without sacrificing quality.

Ultra-High Velocity

Ultra-High Velocity