Meet the challenges of flex PCB processing

The primary challenges manufacturers face are related to processing materials and components at an ever-smaller scale and ever-higher levels of precision.

As the world’s leading innovator in flex laser via drilling solutions, ESI applies decades of laser, optics, and motion control expertise to the application challenges customers face, ranging from simple coverlay cutting to the advanced high-speed blind via drilling and circuit patterning processes. Our family of flex solutions are engineered to deliver the combination of speed, accuracy, and performance our customers need to elevate production and push the boundaries of possibility.

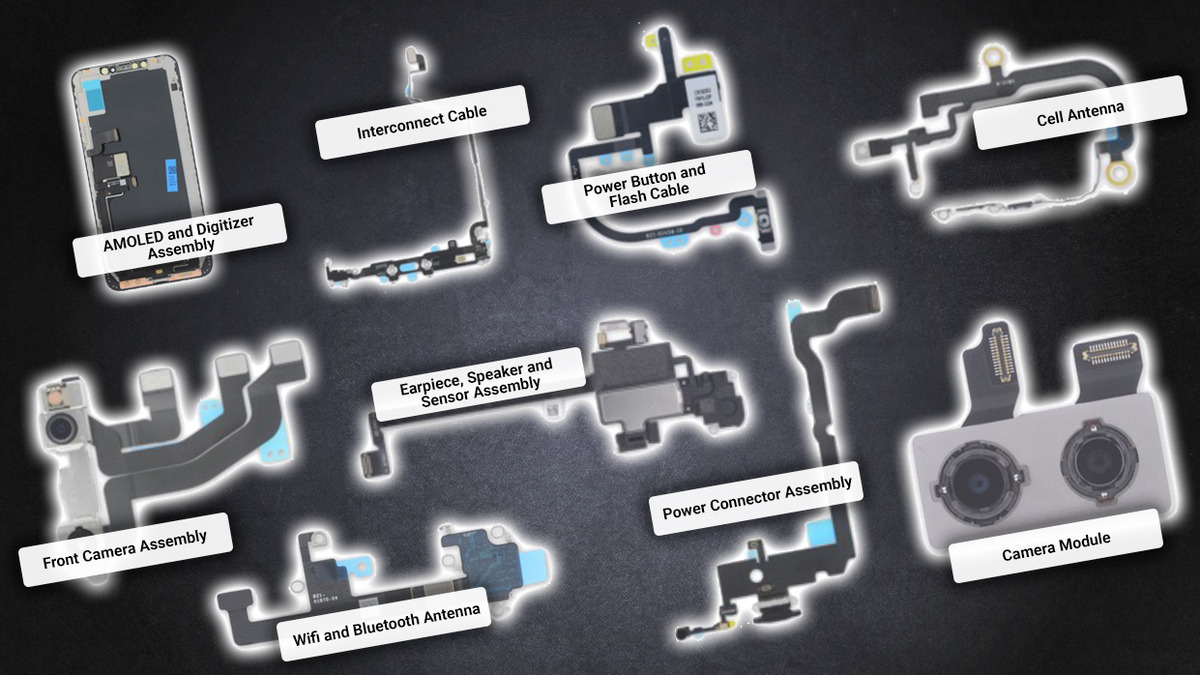

Flex PCB Components Driving Mobile Device Innovation

Via Drilling Solutions for the Evolving Challenges Faced in Flexible PCB Fabrication

- Flex PCB Processing - ESI's flex PCB laser processing systems excel in accuracy, power control, reliability and productivity. We help our customers achieve higher quality production output with higher yields and lower overall cost of ownership.

- Flex PCB Automation - Maintain high-volume manufacturing with flex PCB materials. RollMaster™ by Northfield Automation extracts maximum performance out of your ESI flexible circuit laser drilling tools.

Increase the Performance for CapStone™ Flex PCB Drill Systems with SpotOn™

SPOT ON™ increases performance by delivering a dynamic beam focus capability to high-production Flex PCB manufacturing. This capability enables beam location and control through automated z-mapping and dynamic z-control. With the SPOT ON™ feature, the CapStone™ system maps inconsistencies in height between the chuck, overlay, and panel. Once mapped, the system automatically adjusts the beam spot to deliver quality vias without waste.

Flex PCB Laser System Guide

Capstone |

5335 |

Redstone |

RedStone XP |

LodeStone |

|

|---|---|---|---|---|---|

| Overview | Highest Throughput & via Quality | Flex Industry Standard | Economical System with Broad Capabilities | Economical System with Precision Pulse™ | Shortest Pulse Widths with High Reliability |

| Value Scale | ✓✓✓✓ | ✓✓✓ | ✓✓ | ✓✓ | |

| Positioning | Advanced Tertiary Positioning | Tertiary Positioning | Stage and Galvo Positioning | Stage and Galvo Positioning | Stage and Galvo Positioning |

| Maximum Drill Velocity | 10,000 mm/s | 750 mm/s | 750 mm/s | 750 mm/s | 750 mm/s |

| Laser | esiFlex™ ns UV | ns UV Nd:YAG | ns UV | ns UV | fs Green Fiber |

| Pulse Rate | 150 kHz, 300 kHz | 40 to 90 kHz | 100 to 200 kHz | 100 kHz, 200 kHz, 300 kHz | Up to 1 MHz |

| Average Work Surface Power | 15 W @ 150 kHz | 6.6 W @ 40 kHz | 14 W @ 100 kHz | 14 W @ 100 kHz | 7.8 W @ 1 MHz |

Resources

- Stepping Up to Laser Processing for Flex PCB (807.5 kB, PDF)

- Flex Circuit Laser Processing eBook (4.5 MB, PDF)

- ESI Laser Drill Systems (5.8 MB, PDF)

Ultra-High Velocity

Ultra-High Velocity