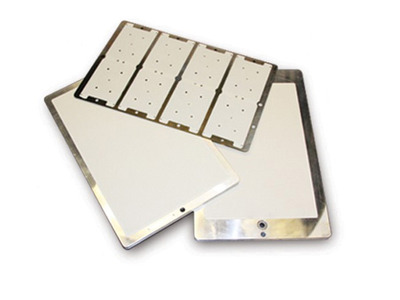

Replacement Carrier Plates for Passive Component Tooling

Overview

Silicone rubber carrier plates provide high-density loading of parts for high-volume chip processing operations

- High-density loading of MLCC components

- Uniform positioning of chips for accurate termination bandwidth

- Compatible with automatic or manual loading machines

Products

Features

Replacement carrier plates for your passive component tooling needs

Silicone rubber carrier plates provide high-density loading of parts for high-volume chip processing operations. Uniform positioning of chips results in accurate termination bandwidth, registration control and superior cosmetic appearance.

Chips can be loaded into the plates by using either automatic or manual loading machines.

ESI’s carrier plates are used for a wide variety of chip components, including multilayer ceramic capacitors, chip array devices, surface mount chip thermistors, multilayer chip varistors, multilayer chip inductors, M.E.L.F.’s, tubular ceramic fuses, chip resistors (5-side termination), piezoelectric actuators, ceramic spacers and grommets, and piezoelectric transducers.

Partner with the industry leader for your tooling needs for high-density chip handling ESI offers a broad selection of sizes and types. Our various designs of replacement carrier plates will help you maximize throughput and minimize manufacturing downtime. Since ESI offers more tooling designs than all other suppliers combined, we can supply all your tooling needs, even custom designs.

Ultra-High Velocity

Ultra-High Velocity