Unleashing the Power of Dual UV and CO2 Lasers

This post explores the technical advantages of the Dual UV and CO2 laser system approach, highlighting its potential to significantly enhance manufacturing capabilities.

Author: Ryan Wagner

Released: April 16th, 2025

How It Works

The process begins with the UV laser ablating the top layer of copper without damaging the dielectric material underneath. For thicker copper layers, a pre-treatment is required. Once the dielectric layer is exposed, the CO2 laser removes the dielectric FR4 material.

Advantages Over Traditional Systems

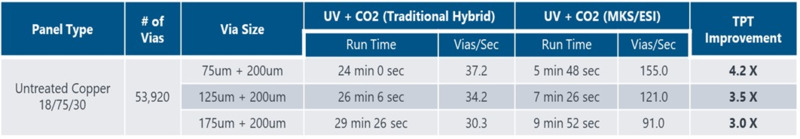

Traditional hybrid systems integrate UV and CO2 lasers within a single system but often struggle with production speed, precision, and thermal management. The dual system approach, which utilizes separate UV and CO2 drills, provides faster and more accurate processing.

Get an in-depth Analysis

To understand how this technology can revolutionize your production process, download our white paper for an in-depth analysis of the Dual UV and CO2 laser system approach. Get the white paper.